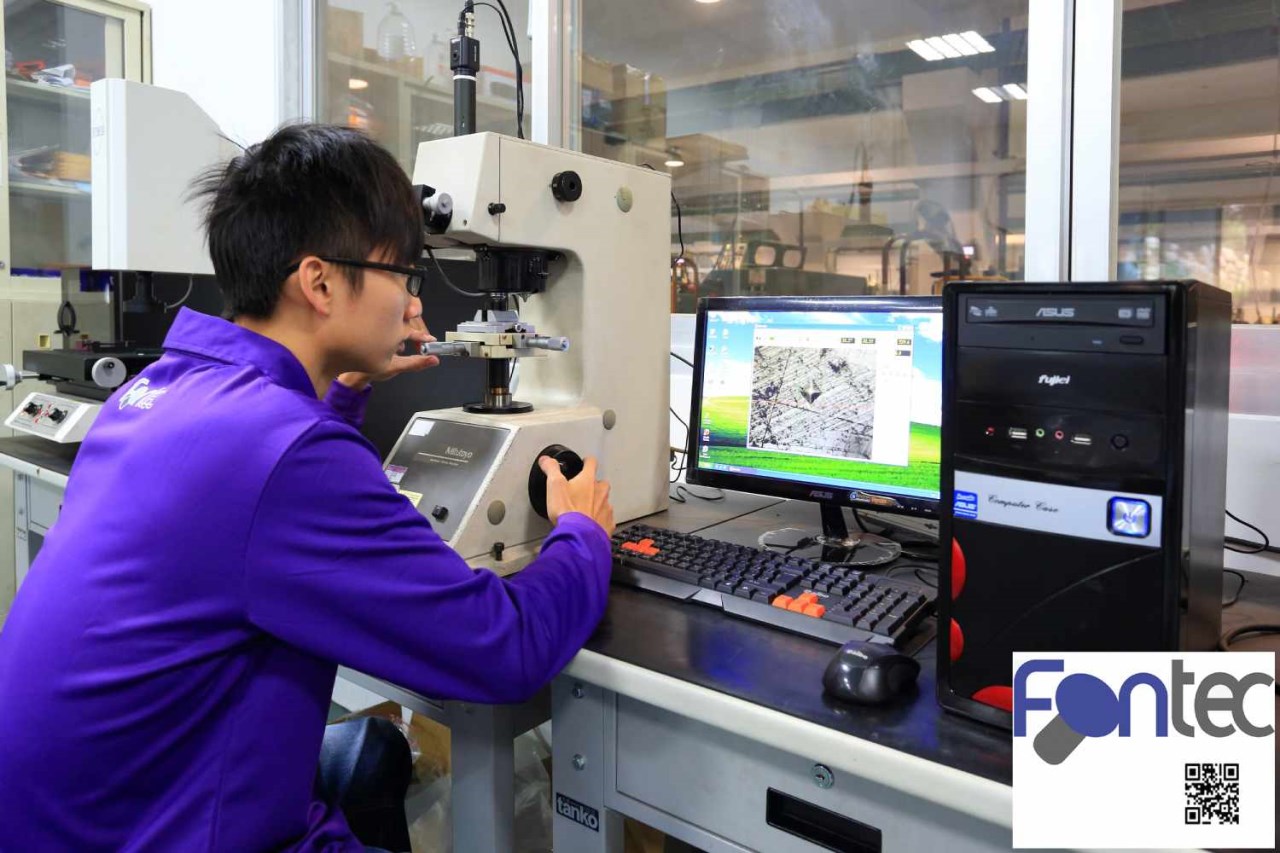

Fontec employs precision Vickers hardness testers (HV) to ensure product quality and structural integrity. This equipment is used to test the surface hardness of various metal materials, suitable for evaluating cold forged screws, rivets, and special fasteners.

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd (UK) as an alternative to the Brinell method. It enables hardness measurement under lower testing loads across a wider range of applications. The test uses a diamond-shaped pyramid indenter to apply force onto the material, with the hardness value (HV) calculated by measuring the diagonals of the indentation.

Vickers Hardness Tester (HV)

Vickers Hardness Tester (HV)

Fontec's Vickers Hardness Testing Equipment

If you require high-strength fastener testing or quality control, Fontec offers comprehensive inspection capabilities including hardness, torque, dimensional, and visual checks. We also provide test reports and sample verification. Contact us for more information.